Key AI-Driven Innovations in Manufacturing and Automotive

“AI is reimagining manufacturing and automotive industries with predictive maintenance AI, AI-driven quality control, and AI in supply chain management. From autonomous vehicle AI to optimising production efficiency, AI is streamlining processes, reducing costs, and enhancing precision.”

Artificial intelligence (AI) is significantly transforming industrial processes in the manufacturing and automotive sectors, driving efficiency, productivity, and innovation. Recent advancements in machine learning algorithms, computer vision, natural language processing, and robotics have enabled manufacturers to optimise operations throughout the production lifecycle. In automotive manufacturing, AI technologies are enhancing design processes, quality control mechanisms, and reshaping vehicle capabilities and customer experiences.

AI in automotive manufacturing is revolutionising design and production. AI-driven quality control systems are projected to be used by 50% of manufacturers by 2025, significantly improving accuracy and efficiency.[1] These systems utilise machine learning to detect defects and ensure high standards, reducing production errors and waste. Predictive maintenance AI is crucial in minimising equipment downtime and optimising maintenance schedules. The global predictive maintenance market is expected to reach $12.3 billion by 2025.[2] By analysing historical data and sensor inputs, AI can predict equipment failures before they occur, enhancing reliability and reducing costs.

Autonomous vehicle AI is advancing rapidly, with the global market projected to grow from $24 billion in 2021 to nearly $62 billion by 2026.[3] AI systems power over 90% of autonomous vehicles worldwide, enhancing safety and reducing human error.[4] These systems include features like adaptive cruise control and automatic emergency braking. AI in supply chain management is transforming logistics and inventory management. The AI in supply chain market is expected to grow at a CAGR of 42.7%, reaching $157.6 billion by 2033.[5] AI technologies optimise inventory levels, improve demand forecasting, and streamline logistics, leading to more efficient and cost-effective supply chains.

AI in Manufacturing

- 1. Capturing Essential Knowledge

-

The manufacturing sector faces a critical challenge as experienced workers retire, taking with them decades of specialised knowledge and expertise. AI systems now offer sophisticated solutions for knowledge capture and transfer that go far beyond traditional documentation methods. Advanced natural language processing algorithms can systematically extract, categorise, and contextualise knowledge from various sources, including recorded conversations, maintenance logs, and operational documentation. These systems utilise semantic analysis to identify relationships between processes, equipment specifications, and troubleshooting procedures. Companies like Siemens have implemented AI-driven knowledge management platforms that create comprehensive digital repositories of manufacturing expertise. [6]

These systems not only store information but also enable dynamic information retrieval based on contextual queries, allowing newer employees to access precisely the knowledge they need when facing specific challenges. The technology also supports continuous learning by automatically updating information repositories as new scenarios are encountered and resolved. This capability is particularly valuable in highly specialised manufacturing environments where equipment-specific knowledge often resides exclusively with long-tenured employees. By transforming tacit knowledge into structured, accessible formats, AI systems enable manufacturers to preserve institutional memory and maintain operational continuity despite workforce transitions. [6]

- 2. Enhancing Worker Productivity

-

AI-powered intelligent assistants are significantly improving worker productivity across manufacturing operations. These systems analyse real-time production data and provide actionable insights directly to operators and engineers. For example, computer vision systems equipped with machine learning algorithms can monitor production lines, detect anomalies in real-time, and alert workers before issues escalate into significant problems. BMW has reported a 5% improvement in production efficiency after implementing AI assistants that provide operators with predictive maintenance recommendations and process optimisation suggestions. [7] Similarly, General Electric has integrated AI systems that analyse sensor data from manufacturing equipment to identify performance patterns and suggest adjustments that have resulted in a 15% reduction in production cycle times. [8]

The technology extends beyond simple monitoring—advanced AI assistants can prioritise alerts based on operational impact, suggest specific corrective actions based on historical data, and even simulate the outcomes of different intervention strategies. These systems effectively function as cognitive extensions for manufacturing personnel, helping them make more informed decisions with greater speed and precision. As these systems mature, they increasingly incorporate feedback loops that enable them to learn from operator decisions, continuously improving their recommendations and adapting to evolving production conditions. This collaboration between human workers and AI systems represents a significant advancement in manufacturing efficiency, enabling personnel to focus their attention on complex problem-solving while automation handles routine monitoring and analysis.

AI technologies are transforming how manufacturing workers acquire and develop new skills through contextual, on-demand learning experiences. AI-driven training systems use augmented reality interfaces to overlay instructions and guidance directly onto physical equipment, creating intuitive learning experiences that dramatically reduce traditional training timeframes. These systems adapt to individual learning patterns, providing additional guidance where needed and accelerating through familiar concepts. At Toyota’s manufacturing facilities, AI-based upskilling platforms have reduced training time for new assembly technicians by 34% while simultaneously improving quality metrics. [2] The technology identifies when workers are performing tasks incorrectly and provides immediate corrective guidance, reinforcing proper techniques in real-time. This approach is particularly effective for complex, multi-step processes where traditional training methods often result in information overload.

Furthermore, these systems maintain detailed records of worker interactions, creating comprehensive skill profiles that help management identify specific competency gaps across the workforce. The technology also enables distributed expertise, allowing specialists to remotely guide less experienced workers through complex procedures with AI-enhanced visual communication tools. This capability has proven especially valuable for manufacturers with geographically dispersed operations. By integrating learning directly into daily work activities, AI-powered upskilling systems are creating more agile workforces capable of adapting to changing production requirements without extensive downtime for formal training sessions. This continuous learning approach represents a fundamental shift from periodic training events to embedded, contextual skill development that occurs alongside regular production activities.

The integration of AI into manufacturing environments is catalysing the emergence of entirely new job categories that blend traditional industrial skills with advanced technological capabilities. These hybrid roles require workers who understand both production processes and the AI systems that support them. Manufacturing AI Trainers, for instance, specialise in preparing and refining datasets to train machine learning algorithms for specific production applications. These specialists must possess domain expertise about manufacturing processes while understanding how to structure data to improve AI performance. Similarly, Human-AI Collaboration Specialists focus on optimising the interface between workers and intelligent systems, ensuring that AI tools genuinely enhance human capabilities rather than creating friction. At Bosch manufacturing facilities, these new roles have been formalised with specific career paths and competency frameworks. The company reports that approximately 8% of its current manufacturing workforce now occupies positions that didn’t exist five years ago. [7]

Another emerging category is Production Algorithm Specialists, who continuously monitor and refine the performance of AI systems in production environments, identifying edge cases where algorithms require adjustment and implementing improvements. These roles typically require a combination of manufacturing experience, statistical knowledge, and programming skills. As manufacturing AI becomes more sophisticated, the demand for workers who can interpret algorithmic decisions, identify potential biases, and ensure AI systems align with operational objectives continues to grow. This evolution is fundamentally changing skill requirements across manufacturing organisations, creating new opportunities for workers to develop high-value expertise that bridges physical production and digital technologies. [7]

The strategic deployment of AI technologies is proving to be a powerful recruitment tool for manufacturers seeking to attract technically skilled workers in an increasingly competitive talent market. Traditional perceptions of manufacturing as a low-tech industry have hampered recruitment efforts, particularly among younger workers. However, organisations implementing advanced AI solutions are effectively repositioning themselves as technology-forward employers. According to research from Deloitte, manufacturing companies that prominently feature their AI initiatives in recruitment materials see a 27% increase in applications from candidates with technical backgrounds.[7] These organisations are successfully communicating how manufacturing careers now involve collaboration with sophisticated technologies rather than purely manual labour. For example, Airbus has developed recruitment campaigns specifically highlighting how engineers work alongside AI systems to solve complex design and production challenges. This approach has resulted in a 40% increase in applications from software engineers and data scientists who previously wouldn’t have considered careers in aerospace manufacturing.[8]

Beyond recruitment, AI is also improving talent retention by creating more intellectually engaging work environments. When repetitive tasks are automated, employees can focus on more creative, problem-solving activities that provide greater job satisfaction. Data from McKinsey indicates that manufacturers with comprehensive AI implementation experience 23% lower turnover rates among technical staff compared to industry averages.[9] As manufacturing organisations continue to evolve their technological capabilities, they increasingly compete with traditional technology companies for talent, requiring more sophisticated approaches to workforce development and retention strategies.

- 6. AI-Driven Quality Control

-

Ensuring product consistency and defect detection are critical in manufacturing. AI-driven quality control systems use computer vision and machine learning models to inspect products with high precision, identifying defects that may be imperceptible to the human eye. AI-powered cameras and sensors analyse vast datasets in real time, allowing manufacturers to detect anomalies early in the production cycle. This reduces waste, lowers production costs, and ensures that only high-quality products reach consumers. AI-based anomaly detection also minimises the need for manual inspections, enhancing overall operational efficiency.

By 2025, 50% of manufacturers are expected to rely on AI-driven insights for quality control. [6] AI achieves 90% defect detection accuracy and improves product quality by 35%, ensuring consistent manufacturing standards. [10] These systems utilise machine learning to detect defects and ensure high standards, reducing production errors and waste. The AI in manufacturing market is projected to reach $68.36 billion by 2032, growing at a CAGR of 33.5%. [10] This growth reflects the industry’s increasing reliance on AI-driven tools for automating production lines, predictive maintenance, and optimising resource allocation.

AI technologies are revolutionising quality control mechanisms in manufacturing, making processes smarter and more efficient. By leveraging AI, manufacturers can significantly improve the accuracy and efficiency of quality inspections, ensuring that only high-quality products reach consumers.

AI in Automotive Industry

- 1. Autonomous and AI-Enhanced Vehicles

-

AI is central to the development of autonomous vehicles, enabling advanced driver assistance systems (ADAS) that enhance road safety and driving experience. AI-driven technologies such as LiDAR, computer vision, and deep learning models process real-time data from vehicle sensors to make split-second decisions. Companies like Tesla, Waymo, and traditional automakers are investing heavily in AI to improve self-driving capabilities. These systems include features like lane departure warnings, adaptive cruise control, and automatic emergency braking, significantly reducing human errors and road accidents.

The global autonomous vehicle market was valued at $54.21 billion in 2022 and is expected to reach $2.16 trillion by 2030.[11] AI-driven systems power over 90% of autonomous vehicles worldwide.[3] According to a study by the Partnership for Analytics Research in Traffic Safety (PARTS), automatic emergency braking (AEB) systems have improved over time, cutting rear-end crashes by 52% in vehicles from model years 2021-2023.[4] Additionally, ADAS technologies are projected to prevent or mitigate 62% of total traffic crashes, potentially saving 20,841 lives annually.[7] By integrating AI, the automotive industry is making significant strides in enhancing vehicle safety and efficiency. These advancements not only improve the driving experience but also contribute to the broader goal of reducing traffic accidents and fatalities.

- 2. Manufacturing Efficiency

-

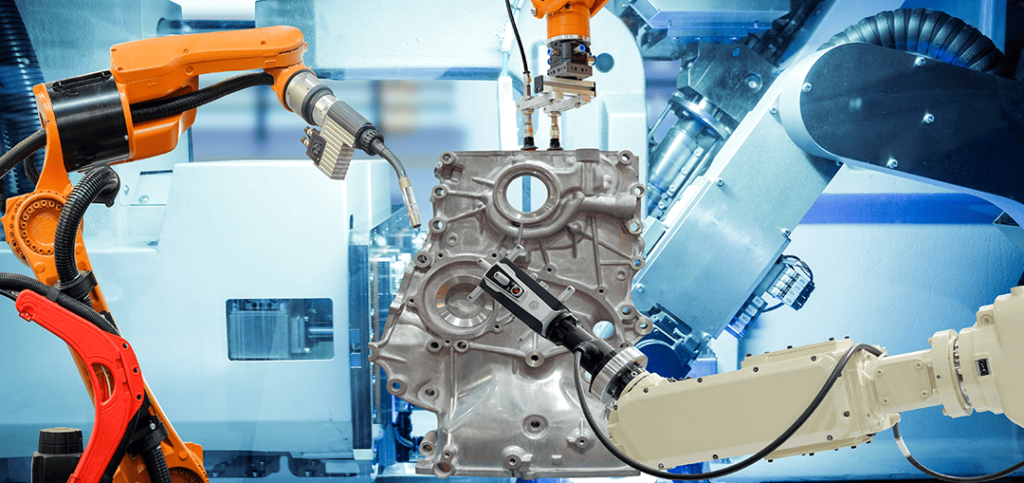

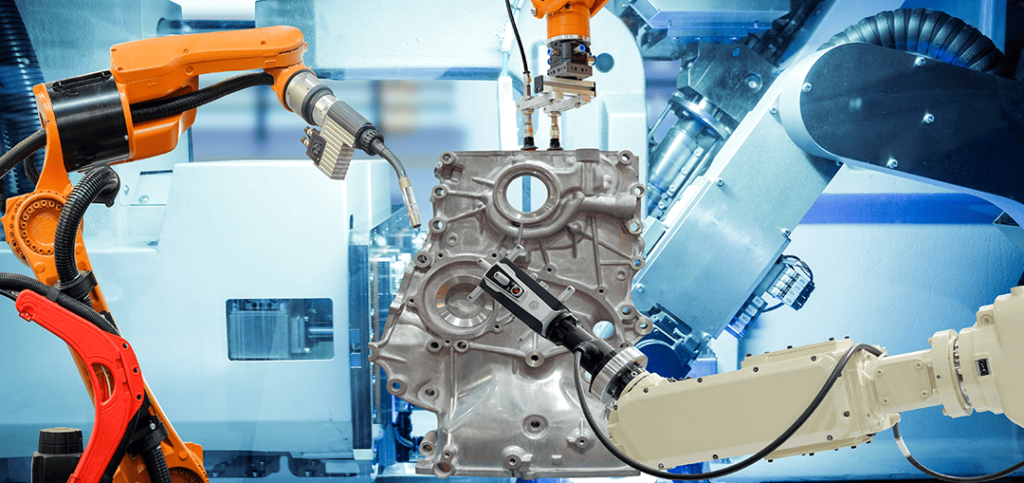

The automotive sector is leveraging AI to optimise vehicle design and production processes. AI-driven simulations assist engineers in testing vehicle components digitally before physical production, reducing prototyping costs. Additionally, AI-powered robotics improve assembly line efficiency by performing complex tasks such as welding and component fitting with high precision. Predictive maintenance AI ensures that production equipment operates at peak performance, minimising downtime and improving overall efficiency.

By 2025, the global AI in automotive manufacturing market is projected to reach $15 billion.[7] AI-driven simulations have reduced prototyping costs by 30%, while AI-powered robotics have improved assembly line efficiency by 25%.[8] Predictive maintenance AI is expected to save manufacturers up to 12% in maintenance costs and reduce downtime by 20%.[9] These advancements enable manufacturers to accelerate production timelines while maintaining high-quality standards. AI technologies are transforming the automotive manufacturing sector, making processes smarter and more efficient. By leveraging AI, manufacturers can significantly improve the accuracy and efficiency of vehicle design and production, ensuring that high-quality products reach consumers.

- 3. AI-Driven Quality Control

-

Automotive manufacturers are using AI-driven quality control to enhance vehicle reliability and safety. AI-powered image recognition systems inspect automotive parts for defects, ensuring compliance with stringent industry standards. Machine learning algorithms analyse historical data to predict potential quality issues, allowing manufacturers to address them proactively. These AI-driven quality control measures significantly reduce recall rates and enhance consumer trust in automotive brands. By 2025, 50% of manufacturers are expected to rely on AI-driven insights for quality control.[12] AI achieves 90% defect detection accuracy and improves product quality by 35%, ensuring consistent manufacturing standards.[8]

AI technologies are revolutionising quality control mechanisms in manufacturing, making processes smarter and more efficient. By leveraging AI, manufacturers can significantly improve the accuracy and efficiency of quality inspections, ensuring that only high-quality products reach consumers. The AI in manufacturing market is projected to reach $68.36 billion by 2032, growing at a CAGR of 33.5%.[13] This growth reflects the industry’s increasing reliance on AI-driven tools for automating production lines, predictive maintenance, and optimising resource allocation.

- 4. Supply Chain Optimisation

-

AI in supply chain management plays a crucial role in predicting demand, optimising inventory, and enhancing logistics operations. AI-powered forecasting models analyse historical sales data and market trends to determine demand fluctuations, preventing overproduction or stock shortages. Intelligent routing algorithms streamline logistics by optimising delivery routes, reducing transportation costs, and ensuring timely distribution. AI-driven automation in warehouses further enhances supply chain efficiency, allowing automotive manufacturers to operate with greater precision and agility. The AI in supply chain market is expected to grow at a CAGR of 42.7%, reaching $157.6 billion by 2033.[5]

AI technologies optimise inventory levels, improve demand forecasting, and streamline logistics, leading to more efficient and cost-effective supply chains. By integrating AI, manufacturers can significantly enhance their supply chain operations, ensuring timely delivery and reducing costs. These advancements enable manufacturers to respond swiftly to market changes, maintain optimal inventory levels, and improve overall operational efficiency.

- 5. Customer Service Enhancement

-

AI-powered chatbots and virtual assistants are transforming customer interactions in the automotive sector. These AI systems handle customer inquiries, provide real-time vehicle diagnostics, and schedule maintenance appointments. Predictive maintenance AI analyses vehicle performance data to anticipate potential issues before they escalate, enabling proactive servicing. By reducing unexpected breakdowns and enhancing service efficiency, AI-powered customer support solutions contribute to improved customer satisfaction and brand loyalty. 68% of support teams report that AI influences customer expectations, while 77% believe it heightens demand for faster response times.[14]

AI technologies are enhancing customer service by providing instant support and personalised experiences. AI-driven chatbots can handle a wide range of customer inquiries, from basic questions to complex troubleshooting, reducing the workload on human support teams. Predictive maintenance AI ensures vehicles are serviced before issues arise, improving reliability and customer trust. These advancements in AI-driven customer service are helping automotive manufacturers build stronger relationships with their customers and maintain high levels of satisfaction.

The Imperative for Reinvention in Modern Organisations

Contemporary organisations face unprecedented challenges in maintaining relevance within rapidly evolving technological landscapes. Customer expectations have transformed dramatically, demanding personalised, instantaneous, and intelligent interactions across multiple touchpoints. Traditional operational models are increasingly insufficient for addressing these complex requirements, creating a critical need for strategic technological reinvention.

Generative AI emerges as a strategic mechanism for digital transformation, offering organisations sophisticated tools to reimagine their operational architectures. By integrating intelligent systems that can dynamically adapt, learn, and generate contextually relevant solutions, enterprises can develop more agile, responsive, and intelligent organisational frameworks. This technological integration transcends mere automation, representing a fundamental restructuring of strategic capabilities.

Leadership plays a pivotal role in driving AI-powered change. Successful GenAI implementation requires visionary executives who can navigate complex technological landscapes, balance innovation with risk management, and cultivate a culture of continuous learning and technological adaptation. Strategic leaders must develop comprehensive AI roadmaps that align technological investments with broader organisational objectives, ensuring sustainable and meaningful digital transformation.

Future Developments

The role of AI in manufacturing and automotive industries will continue to expand, with advancements in generative AI, autonomous decision-making, and predictive analytics shaping the next phase of industrial evolution. AI-driven robotics will become more autonomous, enabling greater flexibility in manufacturing processes. The automotive industry is expected to witness further advancements in self-driving technology, with AI playing a crucial role in vehicle-to-vehicle (V2V) and vehicle-to-infrastructure (V2I) communication.

Generative AI will enhance design processes by creating innovative solutions and optimising production workflows. Autonomous decision-making systems will allow AI-driven robotics to adapt to changing conditions on the factory floor, improving efficiency and reducing downtime. Predictive analytics will continue to refine maintenance schedules, ensuring equipment operates at peak performance and minimising unexpected failures.

Additionally, the integration of AI with sustainable manufacturing practices will drive the development of eco-friendly production methods, reducing carbon footprints across industries. AI technologies will optimise resource allocation, minimise waste, and enhance energy efficiency, contributing to more sustainable manufacturing processes. The automotive industry will benefit from AI-driven advancements in electric vehicle (EV) technology, improving battery management systems and enhancing overall vehicle performance.

As AI continues to evolve, its impact on manufacturing and automotive industries will be profound, driving innovation, efficiency, and sustainability. These advancements will not only improve operational processes but also contribute to broader environmental goals, positioning AI as a key driver of future industrial growth.

Conclusion

AI is redefining manufacturing and automotive industries by enhancing efficiency, improving quality control, and optimising supply chain operations. From predictive maintenance AI in factories to autonomous vehicle AI on the roads, AI-driven innovations are enabling businesses to achieve greater precision and sustainability. As AI technology continues to evolve, its impact on these industries will only deepen, shaping the future of production and mobility.

About the Author :

Dr. Bishan Chauhan

Head – Cloud Services & AI / ML Practice

Motherson Technology Services

Comment

The report highlights AI innovations in the manufacturing and automotive sectors, including predictive maintenance and autonomous vehicles. While AI has enormous potential, what barriers exist in terms of regulatory frameworks and the integration of AI into legacy systems.