From late March through the middle of April of 2020, ARC Advisory Group, in conjunction with automation.com, conducted a web survey to gain insights into how industrial manufacturers are being impacted by COVID-19 and how they are responding to this global pandemic. This report summarizes the results of the survey and subsequent interviews.

Clearly, no company is immune to the impacts or has had to deal with so much uncertainty at one time. As we learned, manufacturers’ responses to the pandemic have been varied. For example, while some manufacturers are decreasing production and furloughing workers, others are increasing, shifting, or relocating production to meet demand. Procter & Gamble, 3M, Georgia-Pacific, BASF, ExxonMobil, Tesla, Ford, GM, ArcelorMittal, and Air Products are all examples of companies that have innovated to manufacture new products or shifted production to meet demand.

Most survey respondents have been investigating new digital technologies and new approaches to be able to support remote and on-site workers, increase manufacturing and product flexibility, and meet supply chain challenges.

For example, companies are using artificial intelligence (AI)-enabled predictive software to determine relative risk based on different scenarios such as: What if the pandemic lasts three months? Six months? Or as long as 19 months? Other pressing questions that were addressed include: “How do we obtain raw materials? What plants in what locations should ramp up production and for which products? How do we transport products when borders have closed? How do we keep our workers safe? How many people will get sick? How can we minimize the impact of COVID-19 to keep workers and their families safe while maintaining business continuity? How can we minimize on-site employees with remote access?

Some manufacturers began the process of rapidly transforming their businesses to be able to produce critical and/or high-demand products. For example, breweries and distilleries have switched from producing beer, wine, or liquor to trying to meet the unprecedented demand for hand sanitizers. Paper product manufacturers have ramped up production and are managing their distribution closely to help fill the empty shelves in many retail outlets. Automotive and electronics manufacturers have responded to government requests (and/or mandates) to produce ventilators, facemasks, and other high-demand personal protective equipment (PPE) for healthcare workers and first responders. Pharmaceutical and medical products manufacturers have had to ramp up their production of current anti-viral medicines, plus reagents and accessories for COVID-19 test kits and develop new capabilities to quickly and safely test a large percentage of the population for COVID-19 antibodies. And, of course, pharmaceutical manufacturers – working in close conjunction with government agencies and academia – face tremendous pressure to fast-track development, approvals, and large-scale production of an effective COVID-19 vaccine. All while dealing with a depleted workforce and major disruptions across the global supply chain.

As we learned, some companies were better prepared with well-thought-out disaster plans. Examples include Georgia-Pacific, BASF, ArcelorMittal, and others.

We learned that cross-training is important to help overcome the new workforce challenges and that those companies that wish they had done more cross training before the pandemic, are doing so now using on-line training for remote workers.

We learned that some manufacturers wish they had put more thought and effort into digital transformation prior to the COVID-19 pandemic. But many of these companies have since adapted and are now adding new digital technologies and digitally enabled solutions as opportunities arise. The ability to readily share and analyze operations and supply chain data remotely, for example, has been critical in some industries, since those data and analyses can now be used to enable collaboration and help make the best data based production and supply chain decisions quickly, even in real time. Most companies, even those with solid contingency plans in place, are operating and making changes and policy updates daily on the fly.

And when people start to return to work, COVID-19 will still have a profound impact on business, operations, the supply chain, and IT. This will continue until an effective vaccine is developed and deployed at scale, early contact tracing efforts bear fruit, and/or faster and more accurate COVID-19 and antibody tests are developed.

IT Support for Remote Workers

Early on, COVID-19 impacted IT organizations. ARC spoke with one company that had over 16,000 people and another with close to half a million people who transitioned rapidly to become remote workers. IT organizations had to modify and upgrade hardware and software almost instantaneously to accommodate remote employees and services. However, obviously, there are situations where large numbers of workers still need to be in the factory to operate onsite production processes. This was particularly true for critical manufacturing and companies with older machines, outdated network infrastructure, and companies without extensive digitalization capabilities.

To get by, companies are upgrading equipment and technology mostly for safety and maintenance reasons. A lot of upgrading is being done remotely or with minimal employees on site, which is emerging as a best practice. Most companies made an immediate shift to video collaboration and some added virtual and augmented reality capabilities to support remote workers. Many help desks had to be re-staffed to be able to support remote workers 24/7. Other companies are using machine learning (ML), AI and specialized cybersecurity technology to identify security breaches and related issues. Employees and customers are engaging online and companies are eliminating in-person meetings, even for those employees working on-site. Other companies are supporting remote workers with better production intelligence using digital dashboards and/or improving controls and increasing the levels of automation.

Demographics of Survey Respondents

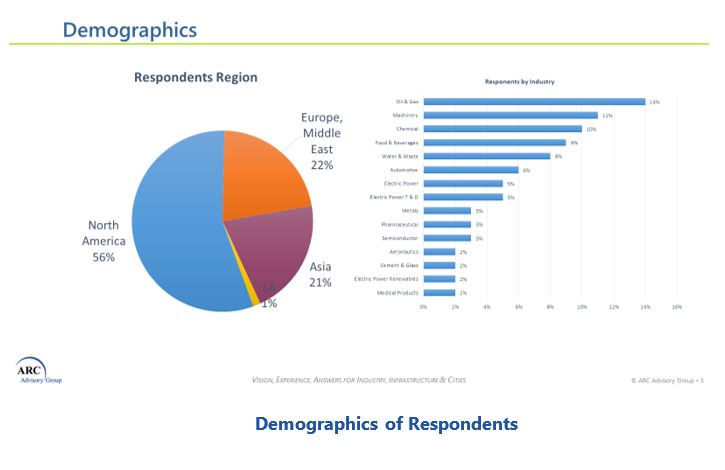

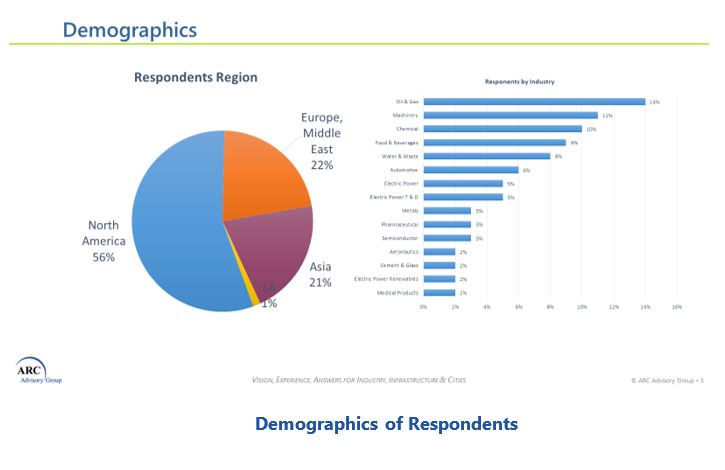

While a total of 159 people participated in the survey, the results were based on 119 end users. This was in addition to individual interviews that were conducted with end users. These results represent a good cross-section of the process and discrete industries. The largest industry represented was oil & gas (14 percent), followed by the machinery (11 percent), chemicals (10 percent), and the food & beverages (9 percent) industries. Fifty-six percent of the end user respondents were from North America, 22 percent from Europe and the Middle East, and 21 percent from Asia.

Current Situation

More than 60 percent of end user respondents to this recent survey stated that they are making changes on the fly daily. Only about 11 percent of the manufacturers agreed that they were closing all manufacturing plants. However, almost 21 percent said it was extremely true and somewhat true that they were closing plants in some locations. Forty-one percent of companies said it was extremely true and somewhat true that their companies are experiencing production and product shortages. Almost 58 percent stated that it is extremely true and somewhat true that they are making changes to the supply chain, while 42 percent said that they do not have enough information about product demand. Almost 21 percent stated that they are closing manufacturing plants in some locations.

ARC believes that some companies are shutting down plants in locations where COVID-19 is having a big impact and shifting production to plants in other regions. This remains a fluid situation.

Impact on Employees

Most respondents expressed their companies’ determination to put employees’ health and safety first while simultaneously maintaining business continuity. Employees that can work remotely are doing so, with over 82 percent of survey respondents stating that this was “extremely true” and “somewhat true.” On-site staff has been reduced with only essential personnel on-site and practicing social distancing. Some companies have reduced staff and offered furloughs to maintain the talent. Eighty-six percent of respondents agreed that these policies have been changing daily. ARC believes that policies will continue to change over the next few months as companies enlist new policies to start to get workers back to the factory or operations site. The longer the pandemic lasts, the more likely companies will have more staff reductions or temporary layoffs.

Impact on Projects and Technology

ARC also asked survey participants about the pandemic’s impact on projects. Over 75 percent stated that all their projects were on hold to some degree; 42 percent are likely to remain on hold until business is back to normal. Others were reprioritizing, postponing, or extending projects.

Impact on Production

Most respondents are providing both remote and on-site services to customers. Over 40 percent of the survey participants are increasing visibility and intelligence in their facilities and reducing production at some plants. Over 30 percent of the respondents cannot shut down; almost 30 percent were closing manufacturing plants located in high-risk areas.

Returning to Normal or at Least the “New Normal”

ARC believes that while it will be a long time before we return to anything that resembles normal, but we will return to a “new normal” level of stability across manufacturing and the supply chain. We’ll see pent up demand for some products, but others may never return to pre-COVID-19 levels, or at least not for a long time before (e.g., a year or more).

Table of Contents

- Executive Overview

- Current Situation

- What Companies Are Doing (or Should Have Done)

- Recommendations

- Appendix: Summary of Respondent Comments

ARC Advisory Group clients can view the complete report at ARC Client Portal

If you would like to buy this report or obtain information about how to become a client, please Contact Us

“Reprinted with permission, original blog was posted here”. You may also visit here for more such insights on the digital transformation of industry.

About ARC Advisory Group (www.arcweb.com): Founded in 1986, ARC Advisory Group is a Boston based leading technology research and advisory firm for industry and infrastructure.

For further information or to provide feedback on this article, please contact RPaira@arcweb.com

About the Author:

Janice Abel

Janice has done extensive research and consulting on automation technologies spanning the entire spectrum of process and manufacturing industries. Her experience includes over 30 years of helping both suppliers and end-user clients develop strategic plans to market, adopt, and use technologies. She has been doing research and consulting for the chemical, oil & gas, pharmaceutical and biopharmaceutical, consumer products, medical devices, and other industries throughout most of her professional career.